Product Details

Permanent Magnet Iron Remover

Full Automatic Iron Removal Machine

Vibrating Sieve

Planetary Mixer

Planetary Mixing Equipment

Why Choose YDX ?

OEM/ODM Customization

Our machinery can be customized to your specific needs, including adjustments in capacity, configuration, and additional features to enhance your production process.

Professional Craftsmanship

With 20 years of experience in the ceramic machinery industry, our team members are highly skilled and bring exceptional expertise to every project.

Customer Service

With a lead time of 15-20 days or less, we also provide full online and onsite technical support and customer service.

Two-year Warranty

Each machine comes with an extraordinary 2-year warranty.

About Us

Foshan Yidaxin Technology Co., Ltd. is a professional manufacturer of ceramic machinery and equipment, boasting a history of 20 years, is a professional factory engaged in screening and magnetic separation equipment, integrating research, development, production, sales, and service. The company mainly produces various types of vibrating screen, electromagnetic separator, permanent separator, mixer machine, electromagnetic whitening machine and pump dozens of series products. Its widely use in ceramic, chemical, mining, food, pharmaceutical, metallurgy, sewage treatment and other industries, These products have been exported to all over the countries such as India, Vietnam, Thailand, Turkey, Bangladesh, and Indonesia, as well as other regions in Southeast Asia etc.

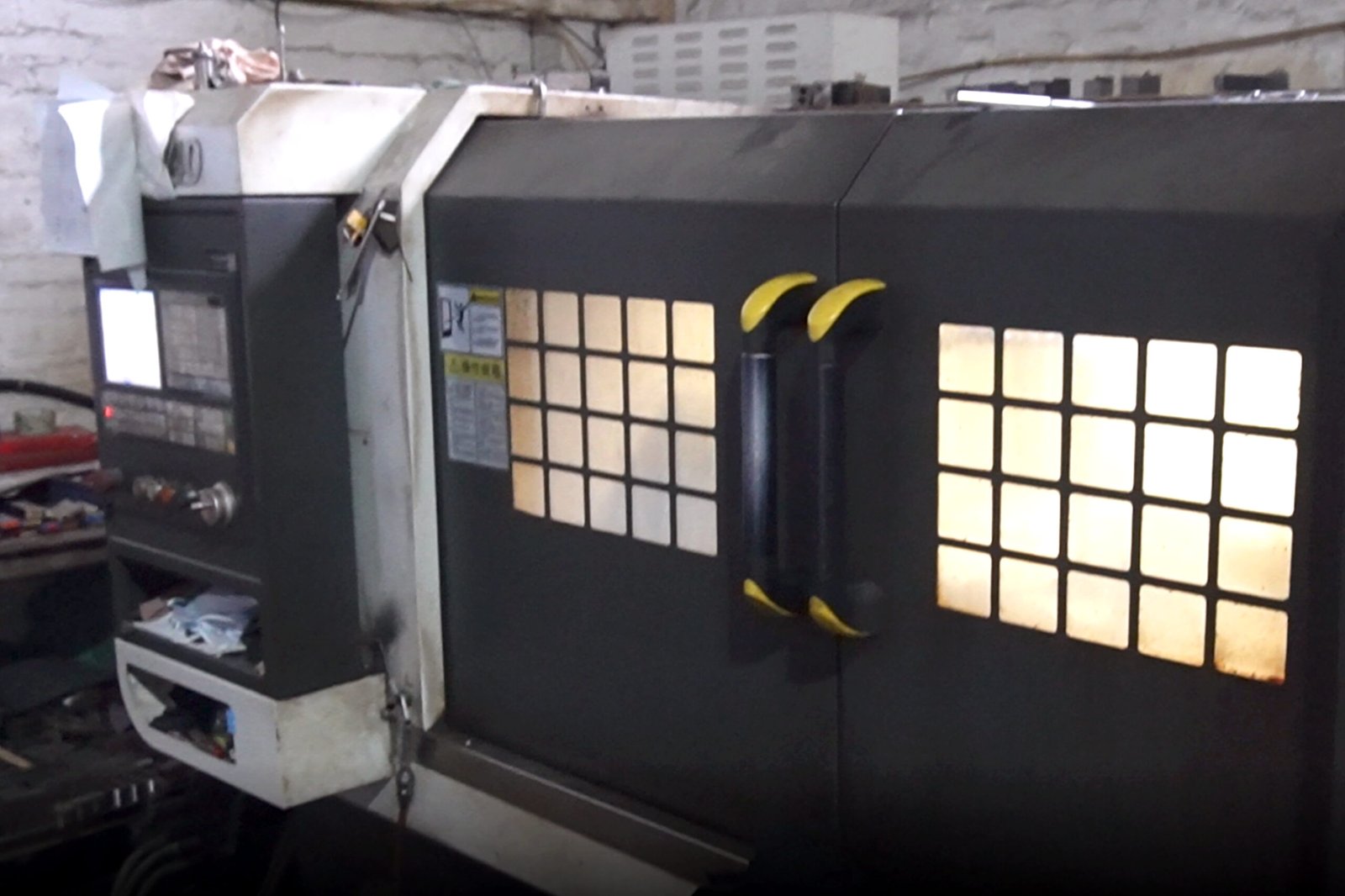

Manufacturing Workshop

Customized Solutions: Understanding that every customer has unique needs, we offer tailored machinery solutions designed to fit your specific production requirements. Our R&D team works closely with you to develop customized equipment that enhances your operational efficiency.

Precision Manufacturing: Our workshop features the latest CNC machines, laser cutters, and automated systems, ensuring every component is crafted with the utmost accuracy and quality.

Innovative Engineering: Our team of experts continuously pushes the boundaries of ceramic machinery technology. We invest heavily in research and development to bring you the most advanced and efficient machinery solutions.

Quality Assurance: Rigorous testing and quality control are integral parts of our manufacturing process. We adhere to the highest industry standards to ensure that each piece of equipment not only meets but exceeds your expectations.

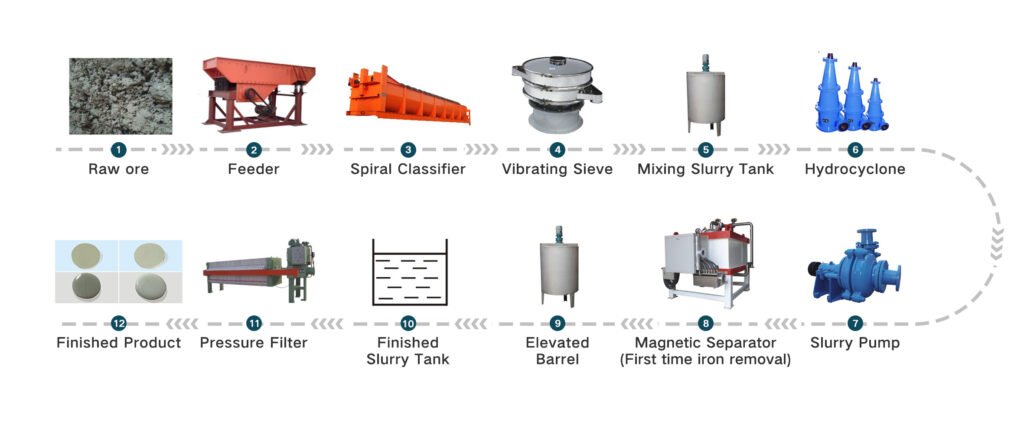

Machinery Line in Factory

Canton Fair

GLOBAL PROJECT CASES

Latest Global Project Cases Have Been Built

Get Started With YDX Now !

Enhancing Your Operations with Trust and Excellence: Provide Our Top-Tier Ceramic Machinery Solutions."

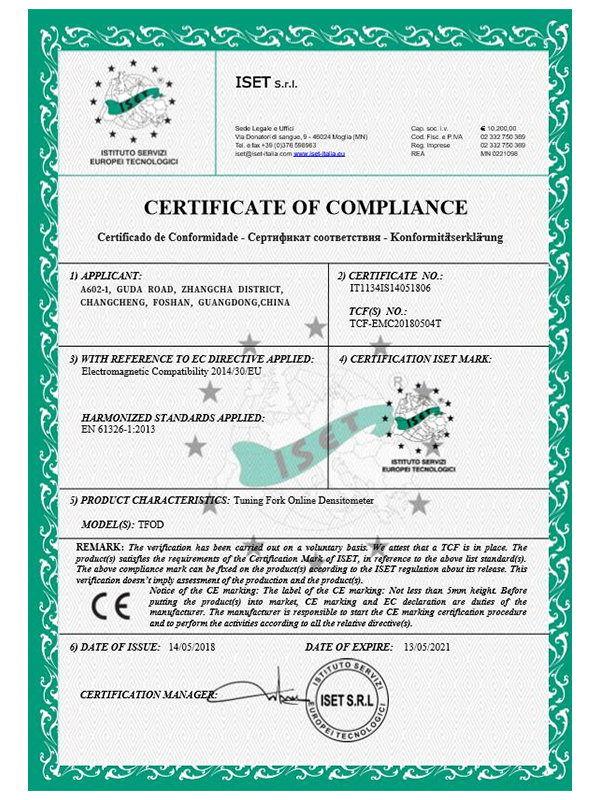

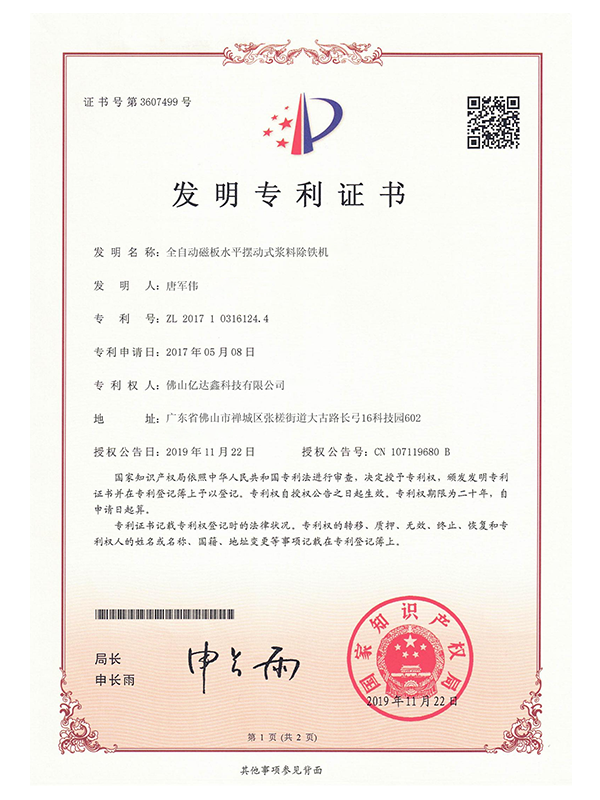

Certification

FAQ

Below you can find some frequently asked questions regarding our ceramic machinery solutions. Please feel

free to contact us if you have any other questions.

Do you provide design services?

Yes, we offer OEM/ODM service, Our custom services ensure that your equipment integrates seamlessly into your production line. Contact us to learn more about our design solutions.

How long does production take?

Most orders are processed within 15-20 days, We also offer rush order services for urgent requirements.

What is your minimum order quantity (MOQ)?

It varies depending on the product. Generally, for our standard machinery, the MOQ is 1 set. We can accommodate smaller orders, but the unit price may be higher.

Where are your machines produced?

All our ceramic machinery are produced in our own factory in Foshan, China.

How to control the quality of the machinery?

Each machine undergoes rigorous quality checks at various stages of production , and we have 48-hour usage quality testing before leaving the factory, ensuring that each machine meets our high standard.

How do you package your ceramic machinery?

We package all our machinery using export-standard wooden cases.

Contacts

foshan yidaxin technology co.,ltd

A602-1, Guda Road, Zhangcha District,

Changcheng, Foshan, Guangdong,China

email address

serena@ydxceramicmachinery.com

Phone Number

+86 13302840788